Completing your abrasive blasting project on time or ahead of time will have a positive impact on your companys success. The media impacts the surface to be finished to erode any unwanted materials or to prep a surface for a coating to be applied after blasting.

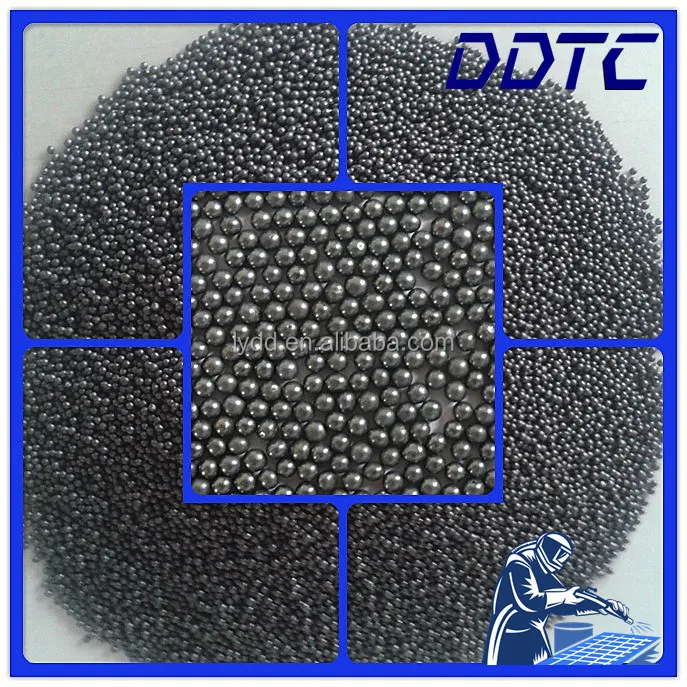

Longevity Sand Blasting Media Steel Shot Abrasive Blasting Grains For Mold Cleaning Operations Buy Steel Shot Longevity Sand Blasting Media Steel Shot Steel Shot Abrasive Blasting Grains For Mold Cleaning Operations Product On

Longevity Sand Blasting Media Steel Shot Abrasive Blasting Grains For Mold Cleaning Operations Buy Steel Shot Longevity Sand Blasting Media Steel Shot Steel Shot Abrasive Blasting Grains For Mold Cleaning Operations Product On

Starblast blasting abrasives are a general-purpose abrasive media.

Abrasive blasting media. We have tested each different media with varying conditions to further educate ourselves with the performance of each material in order to help you get the most out of your production. And these three attributes vary from blasting media to media. Blasting Media We stock a complete line of blasting media for cleaning peening and abrasive cutting at our three locations.

Silica sand has been replaced with other media including grit blast walnut shells glass bead plastic bead and other media. According to an emission report from the EPA silica sand is rarely used anymore for restoration operations due to concerns over Silicosis a lung disease caused by respiratory exposure to dust that contains silica. Find Latest Social Media Manager Job Vacancies in London on Receptix.

Some blasting abrasives like aluminum oxide or silicon carbide cost more up front but are economical in the long run because they can be recycled many times. It may be a mouthful but the correct term for the work we do at American Dry Stripping is media blasting or dry abrasive blasting. Abrasive blasting can involve softer materials like walnut shells and baking.

Abrasive Blasting Media is abrasive that cleans removes finishes and prepares a surface. The ability to recycle a blasting abrasive also varies widely among medias and can have a huge impact on your sand blast productivity and costs. Dry Abrasive Media Blasting.

January 15 2020 admin No Comments. Compared to other blast media such as aluminum oxide crushed glass is less expensive but has different applications. Use pneumatic sandblasting media from Grainger to help make surfaces cleaner smoother softer rougher or etched.

Crushed glass is mostly used as abrasive media for outdoor dry blasting. Professional wet abrasive blasters know that choosing the right abrasive is key to achieving a coating application that lasts. Many suppliers use recycled beer and wine bottles to create blast media.

Silicon carbide is the most aggressive and tough media recommended for general blasting glass and stone etching aggressive deburring scale removal and smoothing components edges. The media is propelled with the use of compressed air or via centrifugal force by a bladed wheel. This abrasive blasting media is widely used in aerospace and automotive industry for blasting applications.

Extra-fine glass bead media can clean thin sheet metals to a smooth dull matte finish. Other types of abrasive blast media like crushed glass or metal slag are primarily used for outdoor blasting and meant to be used and cleaned up. With the right abrasive youll maximize profits by getting the job done faster while expending the minimum volume.

What Replaces Sandblasting. Houston Dallas and Corpus Christi. These two basic components apply to both cabinet and portable sandblaster models.

Dry Blasting uses high-pressure air and abrasive media often made of sand steel grit aluminum oxide or silicon carbide. A coating is only as good as the preparation of the underlying surface. At the point where air escapes the chamber a trap is in place to catch the abrasive media otherwise it would fly out of the chamber as well.

Find Latest Social Media Manager Job Vacancies in London on Receptix. While the common term may be sandblasting many different types of blasting media have replaced sand as the abrasive of choice when it comes to finishing shaping or otherwise modifying a surface. There are many types of abrasive blasting applications each of which requires the use of different types of blasting materials referred to as blasting media.

Contact Us And Take Your Carrier To New Heights. Lets move on now to the most important component of sandblasting. Guide to Abrasive Blasting Media.

These are usually cheaper than other blast media but only good for a few recycles in a blast cabinet or blast. Abrasive blasting can serve many surface finishing purposes such as removing contaminants or previous coatings altering the shape and smoothing or roughening the surface. They are used in steel fabrication and maintenance blasting to remove rust mill scale and weathered coatings as well as surface preparation of other substrates such as aluminum concrete and stainless steel.

Contact Us And Take Your Carrier To New Heights. Choosing the Right Abrasive Media.